ADHESIVE MEASURING SYSTEMS AMS

The Adhesive Measuring Systems AMS (Adhesive Measuring System) measure and monitor adhesive consumption to increase process reliability, production efficiency, and cost transparency.

The measuring systems are available for various melters. The AMS measures and monitors the amount of adhesive used and reports if the amount of adhesive applied deviates from the defined tolerance range. There are two measurement versions, which differ in terms of the accuracy and response time of the measurement. The desired version can be selected depending on the system speed and quality requirements.

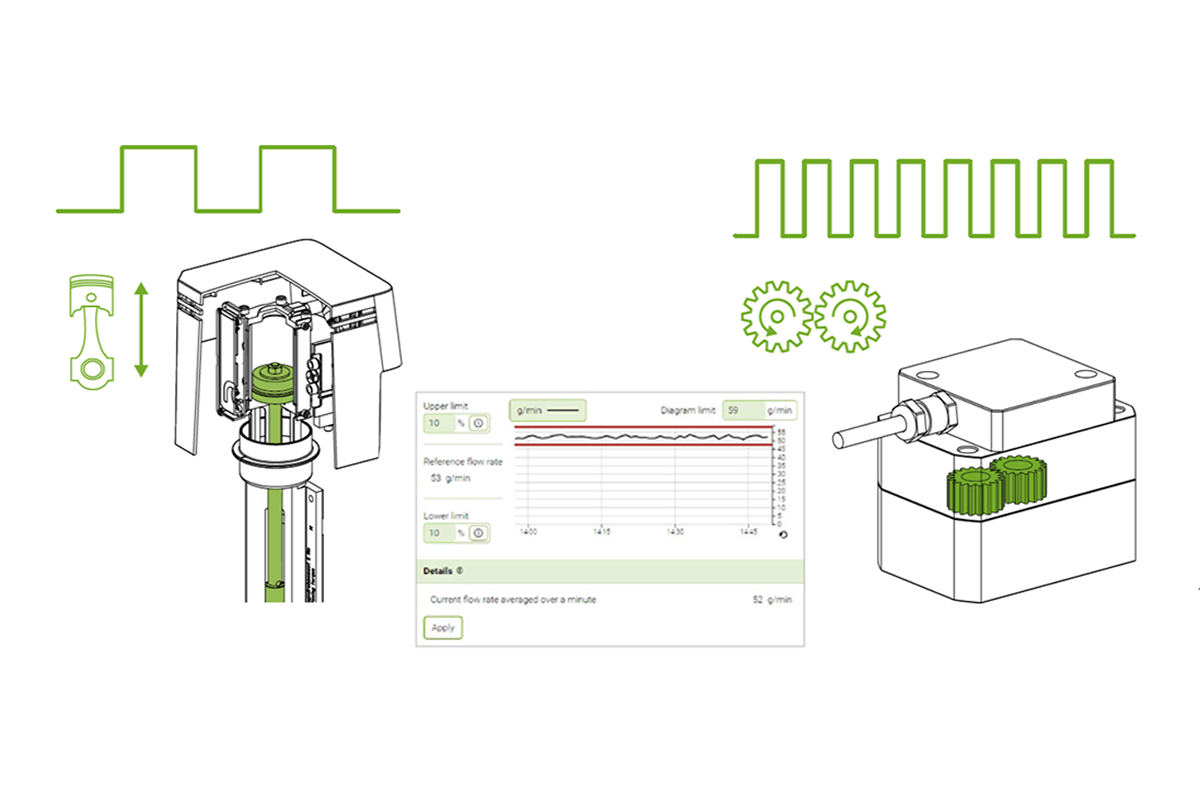

Monitoring adhesive consumption with adhesive measuring system AMS-K (left) and AMS-V (right)

In this version, data is recorded via the piston pump. The adhesive consumption is measured step by step using the pump stroke. AMS-K is integrated as standard in the Vision adhesive melter and is available as an option for Concept Diamond/Stream.

The AMS-V version is more accurate and faster than the AMS-K – it measures the adhesive consumption via the gear flow. The AMS-V measuring cell is available in a version integrated into the glue distributor or as an external unit. AMS-V external is placed outside the adhesive melter between two heated hoses and is particularly suitable for use with large equipment (e.g. JumboFlex, RobaDrum) as well as for simple retrofitting of existing adhesive systems.

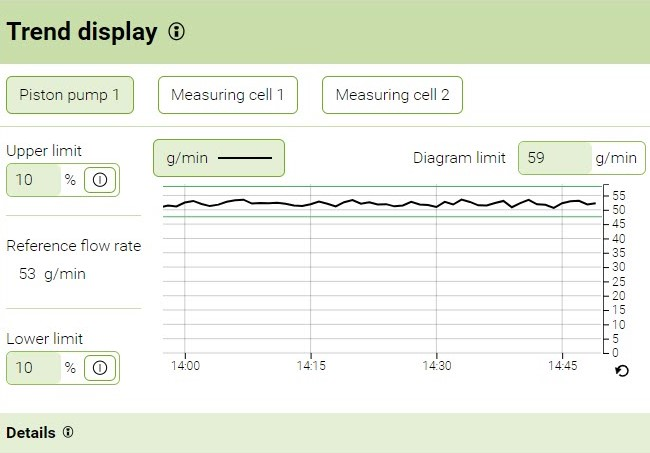

By monitoring the amount of adhesive applied, the adhesive can be reduced to a minimum while still producing a reliably glued product. This increases process reliability and line efficiency. The reduction in adhesive and product waste also results in significant cost savings. The message about the deviation from the tolerance range is displayed on the screen. In addition, further actions can be triggered via a corresponding output signal.

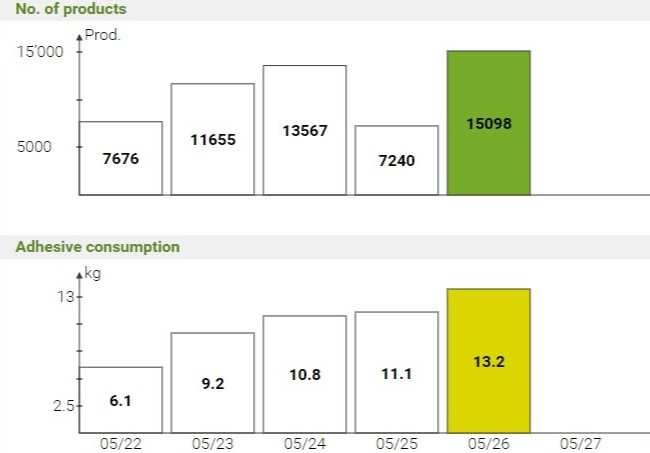

The InfoPlus software is used for graphical representation of the measured data. Evaluations regarding the amount of adhesive applied per product or over a specific period (minute, hour, day, or month) and the number of products produced are clearly displayed. The measured data can also indicate blockages of melter filters and application heads, or application nozzles. The evaluation enables the optimization of settings and processes, which leads to a reduction in costs or prevents unplanned downtimes.

InfoPlus: Tolerance range

InfoPlus: Consumption per day

By analyzing the evaluations, individual production lines can be easily compared with each other, new adhesives and glue patterns can be evaluated or information for procurement and spare parts management can be determined. The measurement data can also be exported for further analysis via a USB interface on the adhesive melter or transferred to a higher-level system via a communication interface (Profibus, Ethernet or real-time Ethernet).

The scope of functions of the application solutions can be easily extended - whether ex-works, after purchase, or as part of a retrofit. Activation is convenient via software key without installation effort.

For the acquisition and evaluation of system and measurement data

Do you need additional information? Contact us today. Our adhesive application experts have the answers to your questions.

Questions?

CloseRobatech AG

","city":"5630 Muri AG","code":"ch","countryName":"Switzerland","countryResponsibleFor":null,"email":"info@robatech.ch","phone":"+41 56 675 77 00","qrCode":null,"street":"Pilatusring 10

","web":null},{"address":"Unique PI Sarl","city":"Promotion SOMACOB BT. A1. N°18, 06000 Bejaia, Algérie","code":"dz","countryName":"Algeria","countryResponsibleFor":null,"email":"mohand.bouaichi@upi-gr.com","phone":"+213 34 12 06 70*","qrCode":null,"street":"Mohand Bouaichi

\nZone industrielle Boulevard TIKAMIRA

","web":"https://upi-gr.com/"},{"address":"UHLIG Representaciones S.R.L.

","city":"Caseros, Prov. de Buenos Aires 1678

","code":"ar","countryName":"Argentina","countryResponsibleFor":null,"email":"info@uhligsrl.com.ar","phone":" +54 11 4734 1593","qrCode":null,"street":"General Hornos 1307

","web":"https://www.uhligsrl.com.ar"},{"address":"Robatech Australia Pty. Ltd.

","city":"Silverwater NSW 2128

Australia

PO BOX 7064

","web":null},{"address":"Robatech Austria GmbH","city":"A-3494 Theiß

","code":"at","countryName":"Austria","countryResponsibleFor":null,"email":"office@robatech.at","phone":" +43 2735 36901 0","qrCode":null,"street":"Im Wirtschaftspark 7

","web":null},{"address":"Robatech BEL","city":"225304 Kobrin

","code":"by","countryName":"Belarus","countryResponsibleFor":null,"email":"robatech.BY@tut.by","phone":" +375 1642 26960","qrCode":null,"street":"Sportivnayastr. 4 BY

","web":"https://www.robatech.com/be/belarus"},{"address":"Ferrecker Ltda / Robatech do Brasil","city":"BR - Curitiba - Parana

","code":"br","countryName":"Brazil","countryResponsibleFor":null,"email":"robatech@robatech.com.br","phone":" +55 41 3123 7200","qrCode":null,"street":"Rua Frederico Carlos Toaldo 11

\nCEP 82.320-360 Santa Felicidade

Woodbridge, ON

CA - L4H 0P8

7600 Highway 27, Unit #12

","web":null},{"address":"Equifar S.A.","city":"CL - Santiago

","code":"cl","countryName":"Chile","countryResponsibleFor":null,"email":"info@robatech.cl","phone":" +56 23 2742 230","qrCode":null,"street":"Vergara 684

","web":null},{"address":"Robatech (China) Limited

","city":"CN - 511400 Guangzhou

P.R. China

1-204 Industrial Building

Tian An Hi-Tech Ecological Park

No. 555 Panyu Avenue, Panyu District

Desamparados, Patarra

CR - Desamparados, San Jose

OFIBODEGAS, Bodega #13

1 km Este del Liceo de San Antonio de

CZ-33011 Hromnice

","code":"cz","countryName":"Czech Republic","countryResponsibleFor":null,"email":"info@kaletech.cz","phone":" +420 378 605 805","qrCode":null,"street":"Planá 20

","web":"https://www.kaletech.cz"},{"address":"Robatech Nordic DK ApS","city":"DK - 8870 Langå

","code":"dk","countryName":"Denmark","countryResponsibleFor":null,"email":"info@robatech.dk","phone":" +45 86 46 14 00","qrCode":null,"street":"Industridalen 2

","web":"https://www.robatech.com/da-dk/"},{"address":"J. C. Scientific Commercial Co.","city":"EG - 11361 Sheraton Cairo

","code":"eg","countryName":"Egypt","countryResponsibleFor":null,"email":"info@jcsc-eg.com","phone":" +202 2267 44 94","qrCode":null,"street":"116 Massaken Sakr Koreish

","web":null},{"address":"Servicios Industriales Internacionales, S.A. de C.V.","city":"SV - San Salvador

","code":"sv","countryName":"El Salvador","countryResponsibleFor":null,"email":"serins@relinsa.net","phone":" +503 2235-2466","qrCode":null,"street":"Colonia Buenos Aires #4YTM-Industrial OY

","city":"FIN - 01720 Vantaa

","code":"fi","countryName":"Finland","countryResponsibleFor":null,"email":"juha.lipponen@ytm.fi","phone":" +358 290 06 230","qrCode":null,"street":"Tiilenlyöjänkuja 9 B","web":"https://www.ytm.fi"},{"address":"Robatech","city":"F - 55300 Chauvoncourt

","code":"fr","countryName":"France","countryResponsibleFor":null,"email":"info@robatech.fr","phone":"+33 3 2989 3614","qrCode":null,"street":"Route de bar le duc

","web":null},{"address":"Robatech GmbH","city":"DE - 65520 Bad Camberg

","code":"de","countryName":"Germany","countryResponsibleFor":null,"email":"info@robatech.de","phone":" +49 6434 94110","qrCode":null,"street":"Im Gründchen 2

","web":null},{"address":"NCA HELLAS Ltd.","city":"GR - 14451 Metamorphosis

","code":"gr","countryName":"Greece","countryResponsibleFor":null,"email":"info@ncahellas.gr","phone":" +30 210 2815 300","qrCode":null,"street":"5, Polemi Str.

","web":null},{"address":"Relaciones Industriales, S.A.","city":"GT - Guatemala City

","code":"gt","countryName":"Guatemala","countryResponsibleFor":null,"email":"relinsa@relinsa.net","phone":" +502 2505-5300","qrCode":null,"street":"1a. Avenida 1-07 Zona 2 El Sauce

","web":"https://www.relinsa.com"},{"address":"Facos S. DE R.L.","city":"HN - San Pedro Sula

","code":"hn","countryName":"Honduras","countryResponsibleFor":null,"email":"serinh@relinsa.net","phone":" +504 2552-6353","qrCode":null,"street":"Barrio Guamilito 7 Calle 7-8 Ave N.O. #62

","web":"https://www.relinsa.com"},{"address":"Robatech Hungary

","city":"HU - 8900 Zalaegerszeg

","code":"hu","countryName":"Hungary","countryResponsibleFor":null,"email":"zoltan.herenyi@robatech.hu","phone":" +36 30 151 151 8","qrCode":null,"street":"Öveges József utca 3/a

","web":null},{"address":"Robatech India Pvt Ltd.

","city":"IN - Dist Thane 421 311 Maharashtra

","code":"in","countryName":"India","countryResponsibleFor":null,"email":"info@robatech.in","phone":" +91 750 666 1880","qrCode":null,"street":"213, E-3 Bhumi World, Mumbai Nasik Rd

Pimplas (Bhiwandi)

Robatech Indonesia

","city":"Ketapang Cipondoh

ID - 15146 Kota Tangerang Banten

IL - 48091 Rosh-Ha‘ain

","code":"il","countryName":"Israel","countryResponsibleFor":null,"email":"info@itas.co.il","phone":" +97 239 026 616","qrCode":null,"street":"Industrial Technology & Services Ltd.

8-10 Hamelacha St, Ind. Park

Robatech Italia s.r.l. u.s.

","city":"IT - 47522 Cesena (FC)

","code":"it","countryName":"Italy","countryResponsibleFor":null,"email":"info@robatech.it","phone":" +39 0547 631700","qrCode":null,"street":"Via Enrico Mattei, 71","web":null},{"address":"Robatech Japan K.K","city":"JP - 5310061 Kita-ku, Osaka

","code":"jp","countryName":"Japan","countryResponsibleFor":null,"email":"info@robatech.jp","phone":"06 4801 4481","qrCode":null,"street":"Katayama building

9-20, 2-chome Nagaranishi

UNCO JET Ltd

","city":"KZ - Almaty 050061

","code":"kz","countryName":"Kazakhstan","countryResponsibleFor":null,"email":"info.uncojet@uncojet.com","phone":" +7 727 381-98-24","qrCode":null,"street":"Utegen batyr 5V/3","web":"https://www.uncojet.kz"},{"address":"AL-Jawad Photo & Trading Co.","city":"KW - 13046 Safat

","code":"kw","countryName":"Kuwait","countryResponsibleFor":null,"email":"info@aljawadkw.com","phone":" +965 2 483 9101","qrCode":null,"street":"P.O. Box 4545

Sahafa Street

Maten 1202 2110

","code":"lb","countryName":"Lebanon","countryResponsibleFor":null,"email":"info@zakkamultitec.com","phone":" +961 1 890 654","qrCode":null,"street":"Zakka Bldg, Fanar, Beirut, Lebanon

PO Box: 90 1352,

MY - Selangor

","code":"my","countryName":"Malaysia","countryResponsibleFor":null,"email":"info@robatech.com.my","phone":" +603 7843 6636","qrCode":null,"street":"No20, Jln PJU1A/13, Tmn Perindustrian Jaya, Ara Damansara,

Petaling Jaya 47301

MA - 20000 Casablanca

","code":"ma","countryName":"Morocco","countryResponsibleFor":null,"email":"unicode@unicode.ma","phone":" +212 522 672 522","qrCode":null,"street":"57, Allée des Jardins

","web":"https://www.unicodemaroc.com"},{"address":"Robatech de Mexico S.A. de C.V.","city":"MX – Querétaro, Qro C.P. 76116

","code":"mx","countryName":"Mexico","countryResponsibleFor":null,"email":"robatech@robatech.com.mx","phone":"+52 442 348 1354","qrCode":null,"street":"Av Peñaflor # 1102

Col. Ciudad del Sol

Novatec Business park Int 97-A

NZ - 4110 Napier

","code":"nz","countryName":"New Zealand","countryResponsibleFor":null,"email":"info@imhengineering.co.nz","phone":" +64 22 164 2126","qrCode":null,"street":"4F/3 Shakespeare Rd

","web":"https://www.imhengineering.co.nz"},{"address":"Codipack R.I., S.A.","city":"NI - Managua

","code":"ni","countryName":"Nicaragua","countryResponsibleFor":null,"email":"relinsa@relinsa.net","phone":" +505 2299 3584","qrCode":null,"street":"Villa Pedro Joaquín Chamorro, semáforos de la Róbelo

5 cuadras al norte ½ cuadra al oeste

NO - 3511 Hønefoss

","code":"no","countryName":"Norway","countryResponsibleFor":null,"email":"info@robatech.no","phone":" +47 32 14 23 75","qrCode":null,"street":"Hvervenmoveien 45

","web":"https://www.robatech.com/no/norge"},{"address":"Ultratec International","city":"PK - Lahore Cantt

","code":"pk","countryName":"Pakistan","countryResponsibleFor":null,"email":"info@ultratecpak.com","phone":" +92 321 844 83 84","qrCode":null,"street":"4-A Abdul Rehman Road,

Imtiaz Shaheed Road

AUMPACK INC

","city":"PH - 1780 Muntinlupa City

","code":"ph","countryName":"Philippines","countryResponsibleFor":null,"email":"info@aumpack.com","phone":"+63-2-8041588","qrCode":null,"street":"Unit 810, Alpap II bldg., Trade Ave.

Cor. Investment Drive, Madrigal Business Park

PL - 44-105 Gliwice

","code":"pl","countryName":"Poland","countryResponsibleFor":null,"email":"info@robatech.pl","phone":" +48 32 270 20 32","qrCode":null,"street":"Ul. Żernicka 35

","web":null},{"address":"Robatech Rus LLC","city":"RU - 197374, Saint-Petersburg

","code":"ru","countryName":"Russia","countryResponsibleFor":null,"email":"gt@robatech.ru","phone":" +7 812 449 56 78","qrCode":null,"street":"Business Center „Lakhta“, office 215

Optikov St., house 4, bldg. 2, A

KSA - Jeddah 21484

","code":"sa","countryName":"Saudi Arabia","countryResponsibleFor":null,"email":"info@alsanad.org","phone":" +966 555 840 301","qrCode":null,"street":"P.O. Box 17305

Tahlia Street

RS - 21235 Temerin

","code":"rs","countryName":"Serbia","countryResponsibleFor":null,"email":"office@mbprint.eu","phone":"+381 21 844 400","qrCode":null,"street":"Novosadska 280

","web":null},{"address":"Robatech SA (Pty) Ltd (Western Cape)","city":"ZA - Cape Town 7405

","code":"za","countryName":"South Africa","countryResponsibleFor":null,"email":"info@robatech.co.za","phone":"+27 21-510 6903","qrCode":null,"street":"24 Shropshire Street

Paarden Eiland

KR - 133-120 Seoul

+82 2 971 0471

robatech@robatech.co.kr

\n

For Woodworking and Building Industry

YOUNG & SUN International Inc.

SETEC Korea

Room No. 203, IS Biz Tower, 147 SeongSu-2Ro

SeongDong-Gu

SE - 302 62 Halmstad

","code":"se","countryName":"Sweden","countryResponsibleFor":null,"email":"info@robatech.se","phone":"+46 35 299 0510","qrCode":null,"street":"Ryttarevägen 18B

","web":"https://www.robatech.com/sv/sverige"},{"address":"JETS","city":"TN - Tunis 1082

","code":"tn","countryName":"Tunisia","countryResponsibleFor":null,"email":"jets@gnet.tn","phone":" +216 71 235 518","qrCode":null,"street":"Tour des bureaux ICC Agence 04 RDC

Centre Urbain Nord

TR - 41040 İzmit - Kocaeli

","code":"tr","countryName":"Türkiye","countryResponsibleFor":null,"email":"info@robatech.com.tr","phone":"+90 262 322 41 57","qrCode":null,"street":"Sanayi Mah. Kozalı Sok. No: 10 Çarşı Yapı

Sitesi C33

UA - Kiev 03037

","code":"ua","countryName":"Ukraine","countryResponsibleFor":null,"email":"info@robatech.com.ua","phone":"+380 68 224 66 42","qrCode":null,"street":"Solomenskaya sq. 2

","web":"https://www.robatech.com/uk/ukraine"},{"address":"Robatech Gluing Technology","city":"Essex SS15 6SW

United Kingdom

*Robatech Gluing Technology is an

authorized trading name of W. H. Leary Ltd.

2 Seax Way, Basildon

","web":null},{"address":"Robatech USA Inc.","city":"Alpharetta, GA 30005 USA

","code":"us","countryName":"USA","countryResponsibleFor":null,"email":"info@robatechusa.com","phone":"+1 770 663 8380","qrCode":null,"street":"1005 Alderman Drive Ste 207

","web":null},{"address":"Vinatech Co., Ltd.","city":"Ho Chi Minh City, VN - 727010 HCM

","code":"vn","countryName":"Vietnam","countryResponsibleFor":null,"email":"info@vinatech.biz","phone":"+84 28 3601 8068","qrCode":null,"street":"38 Street 2 - Cityland, Ward 5, Govap

","web":"https://www.vinatechco.vn"},{"address":"Robatech Gulf FZE

","city":"UAE – Sharjah","code":"ae","countryName":"United Arab Emirates","countryResponsibleFor":null,"email":"info@robatech.ae","phone":"+971 562 55 4966","qrCode":null,"street":"Sharjah Airport Free Zone

","web":null},{"address":"UAB Tecalemit

","city":"LT - 02189, Vilnius

","code":"lt","countryName":"Lithuania","countryResponsibleFor":null,"email":"egidijus.s@tecalemit.lt","phone":" +370 5 210 6210","qrCode":null,"street":"Dariaus ir Gireno g. 177

","web":"https://www.tecalemit.lt"},{"address":"Robatech bv

","city":"NL - 6931 KE Westervoort

Mollevite 5

","web":"https://www.robatech.com/nl/nederland"},{"address":"NOBLEKA SAC

","city":"PE - Lima 41

","code":"pe","countryName":"Peru","countryResponsibleFor":null,"email":"mario.calderon@nobleka-digital.com","phone":"+51-998-308-912","qrCode":null,"street":"Calle Bronsino 320

San Borja

Kovacs Trade Company S.R.L

","city":"RO - Jud. Mures

","code":"ro","countryName":"Romania","countryResponsibleFor":null,"email":"j.kovacs@kovacstrade.ro","phone":"+40 744 624 947","qrCode":null,"street":"Cart. Rodnei 3/3

545300 Reghin

Robatech España, S.L.

","city":"ES - 28021 Villaverde - Madrid

","code":"es","countryName":"Spain","countryResponsibleFor":null,"email":"info@robatech.es","phone":"+34 91 683 82 14","qrCode":null,"street":"C/ Ciudad de Frias, 11 y 13 Nave E

","web":null},{"address":"iNEX Technology Co., Ltd

","city":"TH - Bangkok 10230

","code":"th","countryName":"Thailand","countryResponsibleFor":null,"email":"sales@inextechnology.com","phone":"+66 2 578 8311","qrCode":null,"street":"442 Sukhonthasawat Road

Ladprao

81106 Bratislava

","code":"sk","countryName":"Slovakia","countryResponsibleFor":null,"email":"jakub.buchel@robatech.sk","phone":"+421 918 514 401","qrCode":null,"street":"Hodžovo námestie 1/A

","web":"https://www.robatech.com/sk/slovensko"},{"address":"MB Print d.o.o. Bosna i Hercegovina","city":"Grude, Gorica, 88345

","code":"ba","countryName":"Bosnia-Herzegovina","countryResponsibleFor":null,"email":"marko@mbprint.ba","phone":"+387 39 671 207","qrCode":null,"street":"Brig 96

","web":"http://www.mbprint.ba"},{"address":"Robatech Austria GmbH - podružnica v Ljubljani","city":"1351 Brezovica pri Ljubljani","code":"si","countryName":"Slovenia","countryResponsibleFor":null,"email":"matej.zvajkar@robatech.si","phone":"+386 41 568 573","qrCode":null,"street":"Matej Žvajkar, Prodaja in servis

Tržaška cesta 515

Robatech Headquarters

","city":"5630 Muri AG","code":"hq","countryName":"Headquarters","countryResponsibleFor":null,"email":"info@robatech.ch","phone":"+41 56 675 77 00","qrCode":null,"street":"Pilatusring 10

","web":null}]